As part two of last month’s blog on Unblinding, this month we are covering Inventory Analytics, another new approach that is transforming the world of data aggregation for Life Science manufacturers.

Pharmaceutical Inventory Management Challenges

It’s no secret that life sciences supply chains contain massive amounts of data. This can be advantageous for manufacturers who want to establish an analytical edge and gain insight into their inventory management pipeline. The volume of data can also present its own set of challenges, due to increasing supply chain complexity and the difficulties for manufacturers to estimate downstream inventory levels on their own.

As a result, many pharma manufacturers are beginning to rethink their data aggregation strategies in this area. If left to their own devices, then collection, interpretation, and presentation of inventory data analytics is prone to error and exposes the company to risk.

Inventory Forecasting Challenges

There is an industry need to not only be able to analyze, predict, and present inventory data analytics, but do so in a way that is coherent with the company’s strategy. The pipeline consists of both wholesaler inventory and downstream inventory in distribution channels. The wholesaler piece of the equation is easy to gather and understand because 852 data is available and reported on in a timely cadence by NDC. What manufacturers don’t have clear visibility into is downstream inventory, also known as “rest of market.” Inventory visibility challenges become present when manufacturers don’t have contract terms in place with downstream entities where they are required to report on inventory levels. Accordingly, every manufacturer has to estimate the downstream inventory piece of the pipeline.

Downstream Inventory Visibility Challenges

Wholesale and downstream inventory patterns are volatile and can fluctuate by more than 20%, causing uncertainty in pipeline estimation due to:

- Shifting channel distribution mix

- Product lifecycle events such as launch, loss of exclusivity, stocking shortages, etc.

- Predictability of pricing actions

- Product shortages

- New competitors

Across all life science manufacturers, downstream inventory is estimated to be several billion dollars. Inaccuracies in inventory data analysis could lead to significant dollars that could have been spent on R&D, marketing, or additional production. For pharma manufacturers that have products across multiple therapeutic areas or varying distribution profiles and channel mixes, the complexities are exacerbated. Estimating downstream inventory is a big opportunity for the life sciences manufacturing industry as a whole, especially for companies with less mature processes for forecasting.

For manufacturers using a third-party roll-forward model to calculate downstream inventory, having demand be off slightly can compound to a large variance in a few short years. As a result, simply using syndicated demand data can be a heavily flawed practice. These inventory visibility challenges make it clear that the life sciences manufacturing industry has a need for a well documented and logical methodology for calculating downstream inventory across therapies. Unique characteristics that should also be considered during calculation are:

- Demand curve and seasonality

- Shelf life

- Formularies and strengths

- Channel design

- WAC Price

IntegriChain’s Inventory Analytics – The Cornerstone of Reserve Management

For over 10 years, IntegriChain’s Inventory Analytics tool has been relied on by life sciences finance teams across 40+ pharma manufacturers. It is the industry’s only time-tested source that marries actual supply chain data with the industry’s best non-projected prescription data source to estimate downstream inventory. IntegriChain’s Inventory Analytics provides pharma manufacturers with complete visibility into their pipeline.

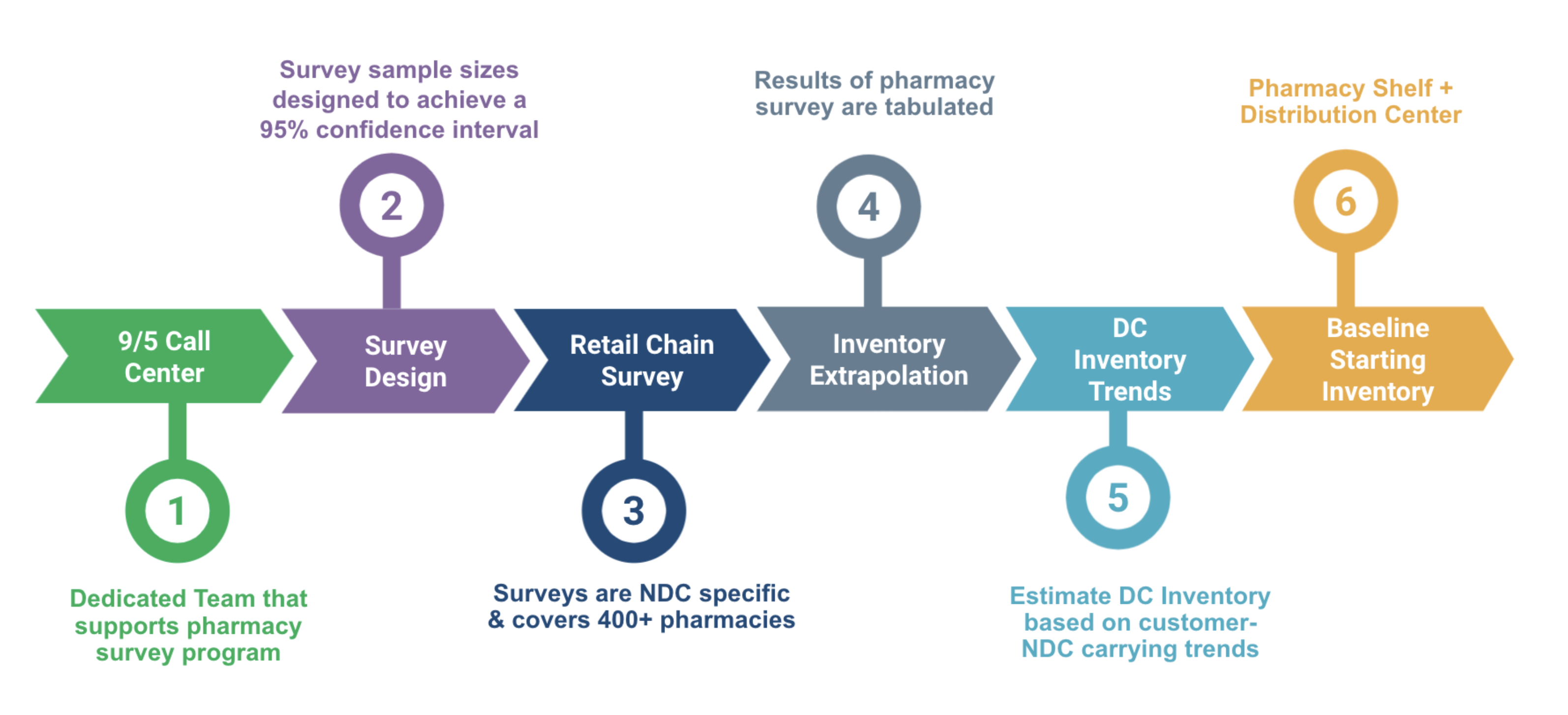

IntegriChain has the industry’s largest pharmacy call program. Accordingly, we can incorporate primary market research into our inventory data analytics model at the NDC level as shown below:

Our Pharmacy Call Program uses actual supply chain data to identify the pharmacy distribution network in order to extrapolate the results. When we have a retail-heavy product (over 65% of distribution in the retail pharmacy channel) we gather a list of 400 pharmacies where the product is downstream. Our call team contacts these pharmacies and asks them questions about product availability. We then take those results and apply them to the entire universe of pharmacies where the product is stocked to approximate the total downstream inventory.

Once starting inventory is established, IntegriChain uses a roll-forward calculation that leverages the manufacturer’s actual channel sales and returns data. As mentioned in our previous blog post on unblinding, IntegriChain’s refined data products have many benefits. One such benefit is we are able to show what went into each downstream channel by NDC by week. After estimating starting inventory, channel sales, and returns, dispenses are subtracted in order to calculate current inventory levels.

Another way in which our customers have benefited from using IntegriChain’s refined channel data is from an industry benchmarking perspective. Our entire channel portfolio is comprised of thousands of NDCs, and we are able to provide manufacturers with competitive market insights. We are able to provide insights on the larger therapeutic areas, explaining what is happening in the market. The benchmarks enable our customers to adjust their strategies to be more competitive.

Conclusion

Processes within the life sciences industry are growing increasingly more complex. Traditional approaches to data aggregation and inventory analytics are rapidly changing. As a result, it’s not enough for manufacturers to simply estimate downstream inventory as they have been for years. IntegriChain continues to fine-tune Inventory Analytics to adapt to changes in the industry. We are committed to providing the most precise tools for our customers to accurately measure pipeline inventory and be at the forefront of inventory analytics.

To learn more about how IntegriChain is changing the game around data unblinding, visit Data Aggregation 3.0 or or listen to our recent webinar, Ushering in a New Era of Channel Data Enrichment.